Dynamic Machine Design

Industrial Expertise Providing Custom Engineered Solutions

Sludge Dewatering: Phone: 1-587-599-5222

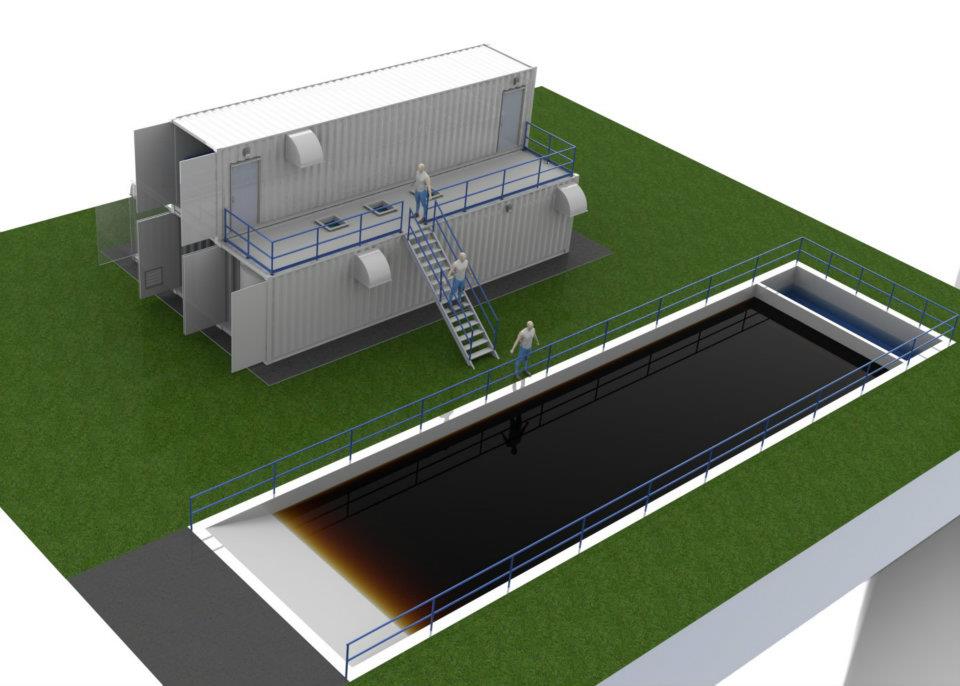

Wastewater Sludge Dewatering.

Watewater Treatment Systems almost invariably create a Sludge as the Solids are removed from the Wastewater stream. Wastewater Sludges generally fall into one of two basic categories, Organic and Inorganic. The percentage of water in the waste sludge can be quite high. For example, Raw Municipal Sewage Sludge, (Pictured to the right in an Internally Fed, sludge dewatering, rotary screen with polymer addition) norally contains over 97% water. When it comes to Industrial, Agricultural, Pharmaceutical, and Food Processing Sludges that must be disposed of, paying to ship and dispose of water is foolishly expensive. This is especially true when water comprises so much of your waste weight and volume. Dewatering is Essential.

We have found that when dealing with Watewater Treatment Systems, many people ignore the Sludge factor. They design Watewater Treatment Systems that produce Sludge, but do little or nothing to deal with that Sludge, leaving it up to the Client to provide a solution. At Dyanmic Machine Design, we work with Municipal, Agricultural and Industrial clients, and we always provide solutions for Sludge.

Organic Wastewater Sludge

Common Sources of Organic Wastewater Sludge are:

- Municipal Wastewater Treatment Plants and Work Camps

- Food Processing

- Agricultural - Farming, Hatcheries, Feedlots, Growers, Stables

- Meat Packaging and Rendering Plants

- Dairies, Cheese Factories

- Pharmaceutical Plants

- Pulp and Paper Mills and Sawmills

- Ship Bildges

Inorganic Wastewater Sludge

Common Sources of Inorganic Wastewater Sludge are:

- Truck, Train and Car Washdown Facilities

- Mining and Mineral Processing

- Pulp and Paper Mills, Sawmills

- Oil Refineries, Well Drilling, Frack Flowback and SAGD Facilities

- Construction Sites

- Gas Thermal, Coal and Nuclear Energy Production

- Assembly & Manufacturing Plants

Common Treatments for Thickening and Dewatering Wastewater Sludge are:

Once sludge is thickened to between 12 and 15 percent Total Suspended Solids (TSS), it is no longer free flowing. Colloidal particles in the mix adversely affect sedimentation processes. Addition of polymers such as Polyacrylamide, or chemicals like Fly Ash, condition the Sludge to improve the efficiency of the Separation Process in Dewatering. Here are some typical industrial technologies and their average dewatering effectiveness.

- Gravity Thickening - 1.5% to 3% Solids

- Dissolved Air Floation (DAF) - 3% to 5% Solids

- Polymer Injection with Dewatering Screen - 3% to 7% Solids

- Geotubes - 50% to 85% Solids

- Centrifuges - 8% to 15% Solids

- Belt Presses - 15% to 25% Solids

- Press Filters - 30% to 50% Solids

- Centrifugal Separators - 25% to 40% Solids

Call or Email Dynamic Machine Design today for a free Sludge Dewatering Consultation.